Features

- Special mineral insulation protects thermocouple form moisture and thermal shock

- Permits operation in high temperature and pressure environments

- Small diameters are ideal when physical space or extremely fast response are critical

- Flexible NACTPAK material allows forming and bending of the thermocouple

- Outer sheath protects wires from oxidation and hostile environments

- Wide range of sheath materials, diameters and calibrations to meet specific requirements

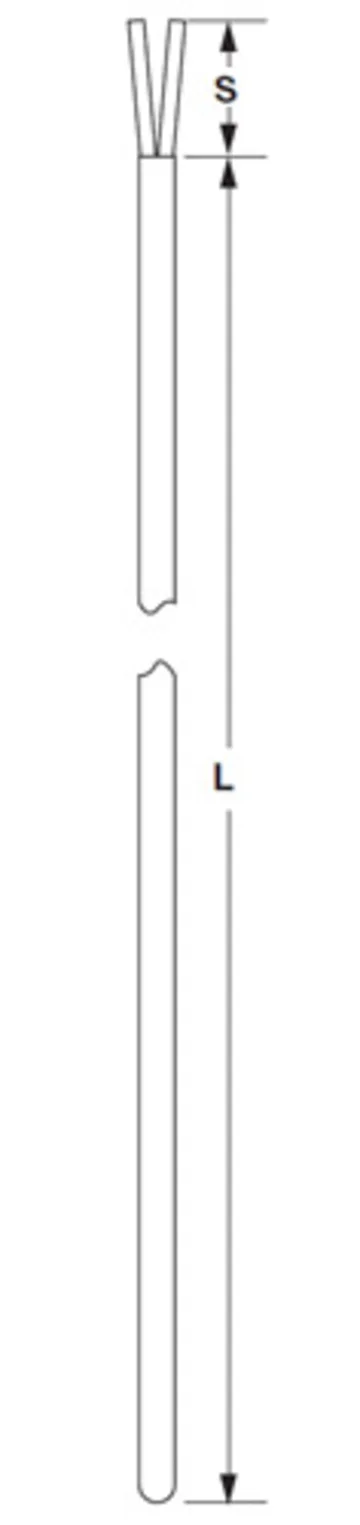

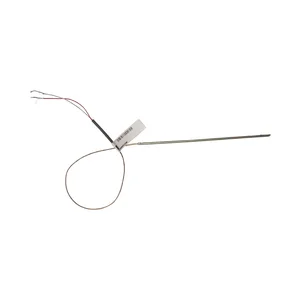

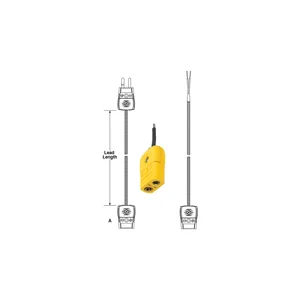

Watlow AB style mineral insulated cut and stripped thermocouples are fast-responding, durable, and capable

of handling higher temperatures than non-insulated thermocouples.

Watlow AB style mineral insulated cut and stripped thermocouples are manufactured with XACTPAK®, Watlow's

trademark for metal-sheathed, mineral insulated (MI) thermocouple material. XACTPAK® responds quickly

because the protective metal outer sheath allows the use of smaller diameter thermocouple conductors. The

rock hard compacted MgO insulation further enhances the sensor's ability to "read" temperature by transferring

heat quickly to the measuring junction.

The XACTPAK® protecting sheath and compacted insulation protects from moisture, thermal shock, high

temperatures, and high pressure to allow the Watlow AB style mineral insulated cut and stripped thermocouple

to outperform its bare wire counterparts in most applications.

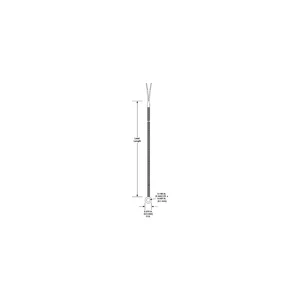

The Watlow AB style mineral insulated cut and stripped thermocouple features mineral insulation for performance

and allows users to terminate the thermocouple for convenience. The AB style is simply a section of XACTPAK®

material, junctioned and stripped. The Watlow AB style mineral insulated cut and stripped thermocouple is the

most basic of all the mineral insulated thermocouple styles. The cold end is stripped and sealed with epoxy to

inhibit moisture penetration. A dual element style allows two instruments to run off the same element, reducing

costs.

Applications for the Watlow AB Style Mineral Insulated Cut and Stripped Thermocouple

Heat treating

Furnaces/kilns

Turbines

Bearing temperature

Power stations

Steam generators

Diesel engines

Nuclear reactors

Atomic research

Jet engines and test cells

Rocket engines

Semiconductor manufacturing

Refineries/oil processing

Catalytic reformers

Food Processing